Enough fun with the video camera. I would be lying if I said I didn’t enjoy running the first train over the whole of the upper deck. A nice reminder of good things yet to come. For now it is back to work.

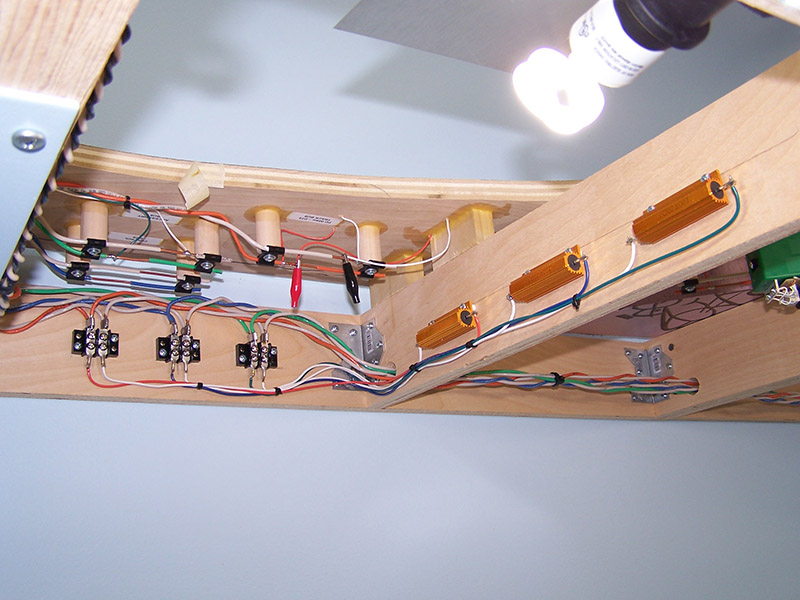

The ballast load of resistance did the trick suppressing the voltage ringing on the power distribution wiring. Evidenced by the “Low Voltage” warning no longer popping up on the RailPro controller. Perhaps you remember these little golden gems:

The root problem of voltage swing is the long distance between the load (trains) and the power supply voltage regulator. It makes the regulator real slow to respond to load changes. When it finally does respond there is wild over and undershoot going on before everything calms down. I believe the RailPro controller warning was being triggered by the undershoot in voltage correction. The warning only occurred when the first loco on the layout was throttled up. Even then it was unpredictable. Although I could sometimes force it to happen by going from standing still directly to notch 8 on the throttle. If there were other locos already running then throttling up yet another loco didn’t trigger the warning. Conclusion: only when the initial load is applied quickly to an unloaded system is there a problem. Solution: permanently load the system. Worked great.

Except…. dang those resistors got warm! They are 100W resistors which are rated 25W without additional heat sinking. They were each dissipating 11W in my configuration. Sounds safe enough, eh? Not so. The operating temperature was over 200°F after a few hours running. You didn’t want to touch them with your fingers. I should have known better. A 10W light bulb gets too hot to touch. My resistors are simply light bulbs that emit no light! The heat didn’t seem to harm the resistors but it did concern me. Not hot enough to be a fire hazard but not a good idea to have three little concentrated hot spots directly below Styrofoam insulation scenery.

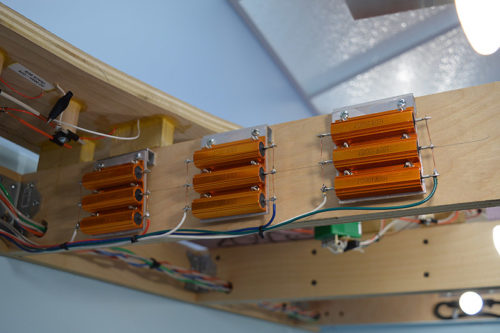

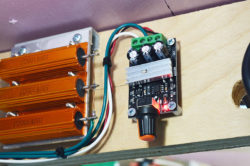

My remedy was divide and conquer. Spread the heat over more radiating area using several resistors so a single resistor doesn’t have to dissipate the full 11W. Three was the chosen number. To replace one 20Ω resistor with three in parallel meant I needed 60Ω units. eBay China doesn’t have 60Ω. In fact, the resistor value selection on eBay China is very thin. The US electronics houses have 60Ω but at $10.00 each!!! Too rich for my blood. The closest I could come on eBay was 100Ω. Three 100Ω in parallel is 33Ω. The current at 15V 33Ω is roughly ½ amp. The original 20Ω resistors flowed ¾ amp. I called it close enough considering the eBay units cost only $2.80. To add a little extra heat sink area the new resistors are mounted on sheets of 1/8″ aluminum. The new assemblies were put in place of the old single resistors reusing the original wiring. Short pieces of aluminum U channel for standoffs created a nice healthy ½” air gap between aluminum plates and wood crossmember.

Calm has returned to LKO land. The new resistor trios barely get warm after hours of operation and the Low Voltage warning has not reappeared.

UPDATE

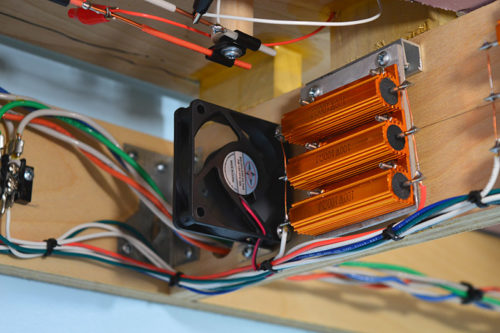

The new resistor arrangement was working fine with the resistors getting no hotter than about 110°F which is not hot enough to damage anything. But for some reason I couldn’t stop thinking about warm resistors. I decided to put this issue to bed once and for all. I present to you forced cooling. With speed control no less! Finally, they operate at room temperature. At last I can put big honkin’ resistors out of mind.

ain’t Ohm’s Law wonderful? hehehe…Nice correction, Alan!

I = V / R = a space heater 🙂

I am in awe sir of your knowledge of electrons and how their almost sole purpose in life ( at least when I am involved…!) is to render ones synapses to gray mush. You however, defeat them at every turn! Well Done.

Alan, another example of your meticulous work. I am curious, did you use any thermal interface material between the resistor bases and your heat sink? Or did you consider that an unecessary expense. Not a major concern, but knowing your attention to detail…

Thanks for the compliments guys. I don’t know as much about electronics as you think I do. I’m just plodding my way through it.

Yes, I used silicone heat sink grease.