As much as I would enjoy getting back to work on the trains, I am forcing myself to stay focused on the workshop until it is reasonably close to being finished. As with everything I do it is a slow process but I am making headway.

The lumber rack

First up was a way to store lumber. In the past it was simply a big pile on the floor along a wall. What a pain it was to find what I needed. Invariably the piece of lumber I needed was the one at the bottom of the pile. You can see the horrible mess of that to the left in the second picture. Solved that problem with a roll around rack. Sticks on one side, sheet goods on the other, with moldings laying flat in a tray on the top and oddsies on the bottom. The iron pipes just slide in holes in the uprights so I can reconfigure them if needed. The sheet of 1/8″ hardboard on the rear keeps sheets from snagging on the uprights when they are slid in from the end. I painted it wall gray so when the lumber rack is against the wall it looks like you can see through it. I forgot to take a picture but there is a second pipe rack above the sheets. I hadn’t stuck the pipes in yet when I took the picture of the sheet good side. I store long narrow strips of flats on the rear pipe rack.

The small panel rack

Next is a way to store panel cutoffs that otherwise would clog the backside of the lumber rack. Also on wheels! The dividers were made from leftover railroad lighting valance.

It has compartments on the sides and rear as well to store even smaller pieces.

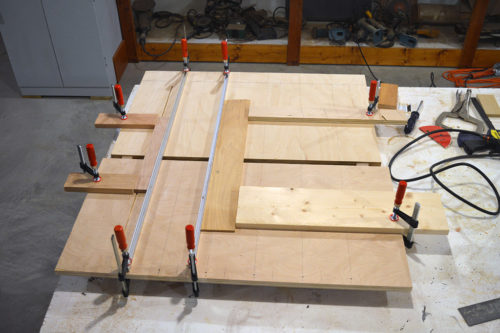

This and the lumber rack were made from material I had on hand plus a couple lengths of 1/2″ black iron pipe. Not piano construction quality but certainly good enough for shop use. Cutting the slots for the dividers required a jig to get it right.

Made nice grooves. Far better than I would have done using just a straightedge to guide the router. They make an under sized bit, called a plywood bit, just for sheet sold as 1/8″ but isn’t really 1/8″. Rather it is the closest metric equivalent to 1/8″. The hardboard fit real snug in the grooves. A little wood glue made them a permanent part of the assembly.

Now the two racks replace what was once a horrific mess. Very happy.

Round things storage

I had accumulated a bunch of very sturdy cardboard tubes. Why I saved them I don’t know but sure glad I did. The tubes plus a sonotube and a steel trash can made a nice way to store long straight thin objects such as dowels, threaded rod, aluminum extrusions, etc. It also worked well to use the odd space I had in the corner that wasn’t suitable for much else.

And one for short pieces as well. In the past I always threw away little short pieces. No more. Whole lot of Elmers holding this together.

The shelves

Finally, the addition that helps the most. There are two shelves for storage totes to store anything I want to store, a specialized shelf for corded power tools, and a voluminous lumber cutoff bin.

The shelves will potentially have a lot of weight on them and because of the design I didn’t want big ole shelf brackets in the way. So the shelves are screwed to studs in the wall, supported by the 4×4 pillars on the near end, and steel strapping to floor joists elsewhere. Doubt there will ever be enough weight on the shelf to tear apart 1″ steel strap!

Below the tote shelves is a shelf made specifically for power tools with cords. I was so tired of tangled cords. That problem is also solved.

Lastly, a large bin to keep short lumber cutoffs.

Starting to load them up.

The cutoffs look like scrap but come in handy so often I keep them. At least now they are confined in a somewhat organized way – 1 by on the left, 2by on the right. Speaking of the cutoff bin I had a bit of an annoyance with it. The electrical plugs had to be raised about 8″. Not a big deal really, just a little drywall work that I didn’t anticipate beforehand. Got lucky with the paint match. Blended in very well.

So far I am just labeling the totes with masking tape as I sort through years worth of stuff scattered in the shop. A tote for electrical, a tote for plumbing, a tote for HVAC, and so on. I’ll label them more permanently and arrange them on the shelves once I figure out what all needs to be there.

Next up is a combination table saw / router table bench.

Looking awesome I can see that you take pride in your work keep it up

Alan,

WOW, you are just to organized,this is the kind of storage I had when I had my Custom Cabinet shop. Don’t have room for these types of storage now. But I really don’t need them, as my layout is totally built. I was lucky in that when I built the bench work I had my commercial shop and built everything there and brought it home and down into the basement.

P.S. Looking forward to visiting you to test your Ring Engineering system.

Wow! Just WOW!

Alan, I very much enjoy keeping up with your activities on this blog. Thank you for taking the time to share all the great info with us.

Alan. glad to see you back inside again. I guess the new fence took longer than expected. Awesome workshop organizers – beats my piles of stuff behind the layout curtains. I’m jealous. Looking forward to more train activities.

You, sir are a MANIAC! Love the organization, you can never have enough. Well done.My only question: where is the automated robotic assembly line going to go?

Good to see the fire extinguisher hanging on the end of the rack! Alan I love seeing your builds, even extras like this you can see your planning & engineering skills in full flight.

You remind a lot of my father who builds jigs, holders, and just about everything he needs for his wood working ventures himself.

Fantastic post, and good to see you back into the swing of things again too… Jas.

You know what Alan I check in everyday to check out the old post and to check on new posts and I can say with 100% this post tells me that I need to be more organize with y layout room as seen in my YouTube videos it’s bad lol. In case you would like to see my video’s to tell me it’s bad lol my YouTube channel name is bald8bil

Barn door?

Looked in on this latest post and had to laugh a little.

Isn’t the bench work all built? And aren’t those nifty control panels all done?

Now the workshop? Alan, I believe you are human after all.

Thanks for all the inspiration.

Hi Alan

You have been quiet for a while now – I hope all is well?

Best Regards

Rob Clark

Rob,

All is well. Just otherwise engaged that’s all. Thanks for your concern.

I’m checking in to see if you and your family are doing okay

Billy,

I am touched by your concern. Yes, we are doing fine. Life has gotten a bit hectic thus keeping me away from trains for the moment. I’ll be back, you can count on it.

Any update on how the layout is coming along? Almost a year since your last post. Hope to see what you have done since your last post as I really enjoy your blog.

Regards,

Rod Souza

Rod, no update yet. Keep the faith brother. I will be back to the train room just not yet. Life is keeping me really busy right now.

Just letting you know that your updates are missed. Looking forward to more great work.

Thanks Art. I’ll be back hopefully soon.

Any Chance you have plans for the lumber rack?

Not plans per se, here is a side and front view illustration of the lumber rack. I added a scale.

https://lkorailroad.com/wp-content/uploads/2020/06/lumber-rack.pdf