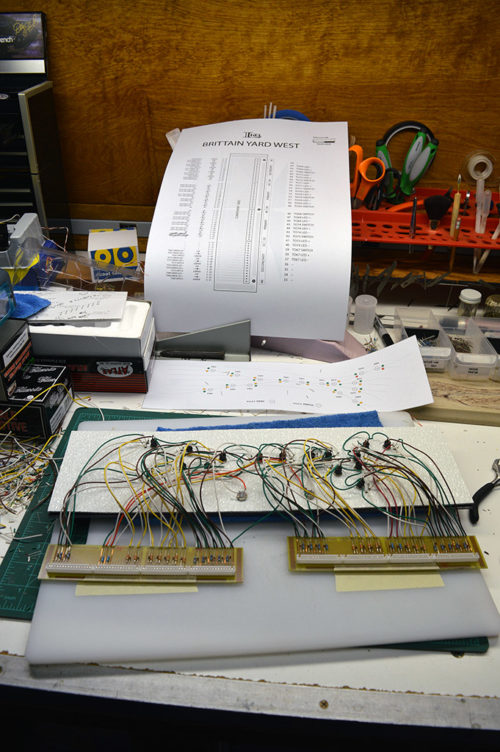

Progress! 9 down, 7 to go.

Allow me to share a painful lesson learned – check that all LEDs are in the correct position before assembling a panel. It happened on the Brittain Yard West panel. After several hours work the panel was all soldered together and placed in its enclosure. As I do with all of them, I began testing to verify the wiring was correct. Halfway through testing, I insert the connector expecting a green LED at turnout #40 only to see the yellow come on. So I reverse the pins and the green LED lights. Maybe I accidentally reversed the wires on the connector board. Then I realize the yellow is way too dim and the green way too bright. Ug. The only possible explanation is the LEDs are reversed in their holes. Sure enough that was the problem.

I had to un-solder every wire then completely disassemble the panel face just to switch two LEDs around. Then re-solder every connection a second time. Yeah, I was very mad at myself for not checking first. A whole weekend down the drain. Won’t make that mistake again.

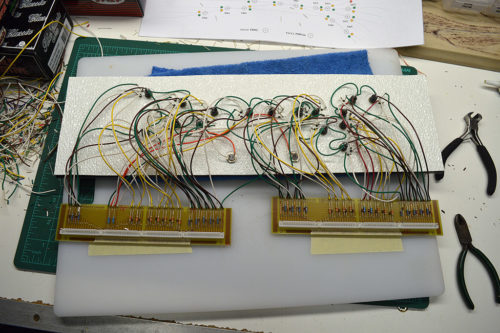

Other than that one misfortune the panel construction is proceeding nicely. Slowly but moving along. This has been my view for the past several weeks and likely several more.

The iron is hot. Gotta go.

I admire your commitment Alan, it’s like ground hog day and I don’t think my patience would last with a project that intense. The signal wiring has almost beaten me on several occasions…

Again the level of your electronic engineering and planning is astonishing. A real work of art! 👍🏻

everything is looking awesome keep it up my brother p.s. maybe you can upload a video of all the work you have done to your layout

Alan – persevere…just imagine how BORING it would be if we never made mistakes…panels are magnificent!

Alan – To quote Robert Burns; “The best laid schemes o’ mice an’ men / Gang aft a-gley.” I can sympathize, but one must persist. The panels are a knock-out!

Thanks guys. Not every footstep in life is forward, eh?

I really love your panels and wish to replicate your idea on our club’s new layout. I do have one question. You said you had to un-solder every wire and then completely disassemble the panel face just to switch two LEDs around. Is this the same procedure you would have to do if a LED burned out and need replacing?

Art

Yes, the same procedure. That is why I first tried the push-on connectors. They would have made the process much simpler but they didn’t work well. Fortunately LEDs last a very long time.