Well, how about that. I have 16 completed control panel enclosures.

15 of them went together smooth as silk. One, I can only deduce, was possessed by demons.

Control panel #14, a half width unit. When I went to attach the side blocks I realized I had glued the frame together upside down. Duh. Instead of tilting up, it tilted down. No biggie I thought. I carefully sliced the corner blocks in half with a modeling saw and then a quick snap to break the corners apart. Worked great. Didn’t mar the outside faces or the miter cuts at all. A little sanding to get rid of the dried glue and it was right back to glue-up. Home free, right? Wrong. While drilling one of the sides for the bottom panel screw, the drill bit snaps off below the top of the hole. No way to get it out. Oh well, it’s the bottom panel. Can’t see the bottom. I drill another hole to the side of the original. Countersink and shank drill a second hole in the bottom panel to match. Okay, all that’s left is to fasten the bottom panel. Screw number one then screw number two. Snap! The head of screw number two snaps right off. Are you kidding me? I wasn’t even twisting it very hard. Fortunately, there is a little nub of the screw sticking out of the wood that I can get a small set of vise-grips onto. A new screw went into the same hole with no trouble at all.

No problems on fifteen panels and three problems on one panel. What are the odds? Panel number 14 fought me to the bitter end. I don’t know if it was my cursing or the threat of an exorcism that made it finally relent. In the end, I have enough completed panel enclosures for the entire upper deck. All’s well that ends well I suppose.

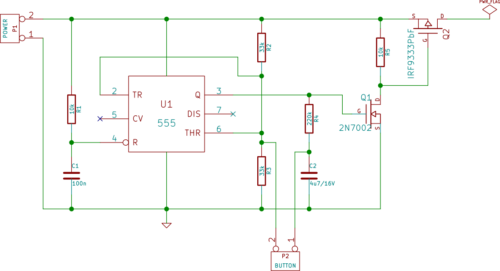

On a somewhat related note, my push on – push off relay assemblies arrived from China. Since all my panel switches are momentary contact and there are some things that need to have power continuously applied I needed a way to push the button once to turn something on and then push the button again to turn it off. In other words, make a momentary contact switch function like a toggle switch. There are any number of ways to go about this. A very common circuit found in many electronics textbooks and all over the web uses the venerable 555 IC timer chip to perform the on/off function. Here is a typical schematic:

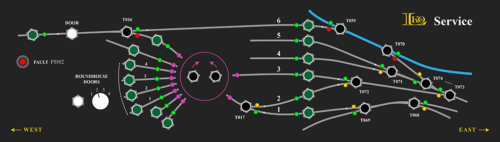

I was going to build a bunch of these circuits except replacing Q2 with a relay. And then I stumbled onto the same circuit pre-assembled on eBay:

$2.00 Yes, only two dollars! With free shipping! I can’t buy the parts to make my own for twice that amount. Now, I enjoy making my own stuff but c’mon, two bucks? Stab the Buy Now button. A whole box of them arrived today. These will be used primarily to turn on/off power to track in the Brittain Yard service area. Basically, for every green button on the control panels.

I have a lot of connector board soldering to do. Stay tuned.

no part number or seller info for the relay- what a find !!

http://www.ebay.com/itm/DC-5V-12V-24V-1-Channel-Latching-Relay-Module-With-Touch-Bistable-Switch-MCU-/112248967119?var=&hash=item1a228f4fcf:m:m5e_E7RI0_XBQ5ry59PMWPw

Price has gone up 43 cents since my purchase.