I am almost all the way around the layout with the panel wiring. It is proceeding along smoothly with no major uh-ohs. The traveling workstation is working great.

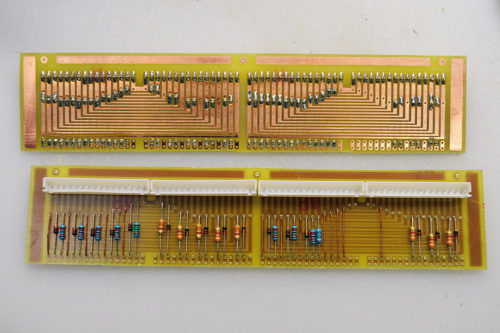

Most of the panels connect directly to a track module. Some, however, are slave panels meaning they are daisy chained from other panels and are not directly connected to a track module. This daisy chaining is why there are redundant connectors on the backside of the panels.

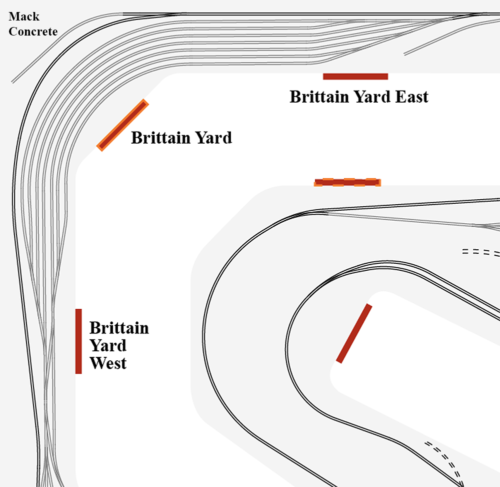

Brittain Yard is a good example of daisy chained panels. There is a West Brittain Yard panel and there is an East Brittain Yard panel. Each panel is at its respective end of the yard and wired to its corresponding track module. In the middle of the classification tracks is a panel simply labeled Brittain Yard. From this middle panel you can control turnouts on either end of the yard. The middle Brittain Yard panel has but a single direct connection to a track module – the turnout for Mack Concrete. Otherwise, all connections to the center panel are to the two yard end panels.

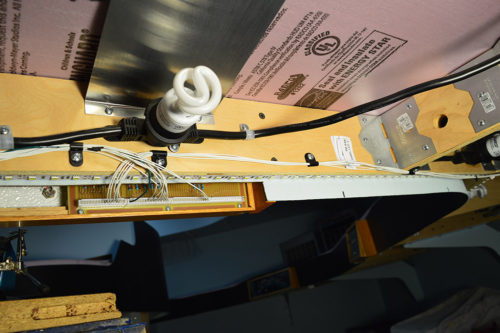

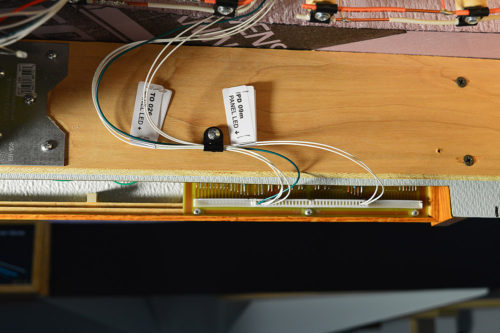

The wiring harness connecting panels to slave panels is routed along the benchwork immediately behind the fascia. Here you can see the harness from Brittain Yard West to the center panel before being secured out of view.

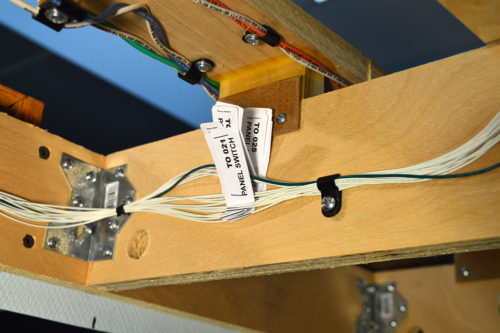

I am labeling the daisy chain harnesses the same way I did the track module wires except the daisy chain wires have labels on both ends. I think I am a labeling fanatic. There are labels on everything under the layout. Handy for a guy like me who has trouble remembering what I had for supper last night!

A few photos will give you the gist of what is happening. Many of the empty connectors in the photos will get filled as I install the remaining slave harnesses.

I did have one little setback – ran out of wire. Way back when I first began building the railroad I bought a 2000′ spool of 22AWG wire on eBay for $25.00. Seemed like a good deal. I have since learned it was a phenomenal deal.

The label on the spool indicated the wire was part number M22759/32-22-9 made by TE Connectivity. A little Googling and I found the data sheet.

I knew when I first used this wire it was no ordinary vinyl clad hookup wire. The insulation is very thin and very flexible yet rated at 600V. Most hookup wire is 65V or less. It strips nicer than any wire I have worked with in the past and it has superb heat resistance. The soldering iron doesn’t curl or burn it the way it does vinyl insulation. Additionally, the smaller overall diameter due to the thin insulation makes wire bundles smaller and easier to work with. According to the data sheet the insulation is indeed not vinyl but rather something called ethylene tetrafluoroethylene (ETFE). Well, I don’t know what that is but I sure do like working with it. So, I set off to find the best deal on M22759/32-22-9. That ended up being Arrow Electronics at $152.40 for 2000′. See why the original eBay purchase was such a phenomenal deal? BTW the same seller still sells the same wire on eBay but he has figured out he was selling it way too cheap. He now wants more money than Arrow does for the same wire. My wallet may be a little lighter but at least I have enough wire to finish my current panel wiring task as well as the rest of the layout.

Be back when I finish the panel wiring.

Leave a Reply