What I started over seven months ago is finally finished. Sixteen control panels built, tested, and ready for installation. While there certainly were trials and tribulations along the way, it was by and large an enjoyable adventure.

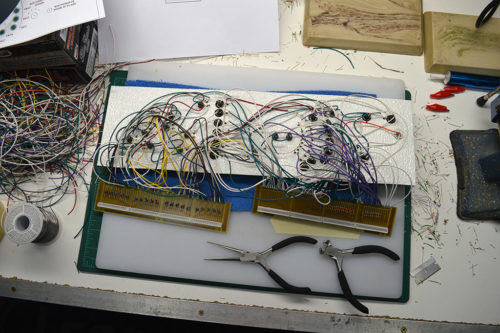

Speaking of along the way, check out the pile of wire trimmings that were generated. I’ll keep these for future work so not as much wire waste as it appears.

The poor workbench didn’t get tidied up the whole time. It stayed in control panel build mode.

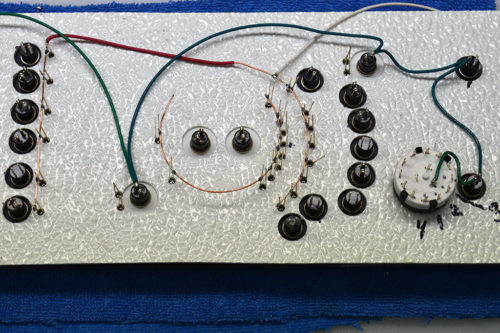

I saved the most interesting build for last – the Brittain Service panel.

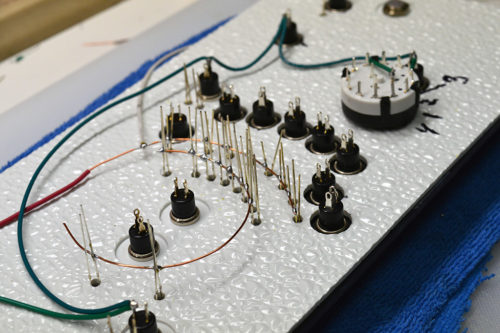

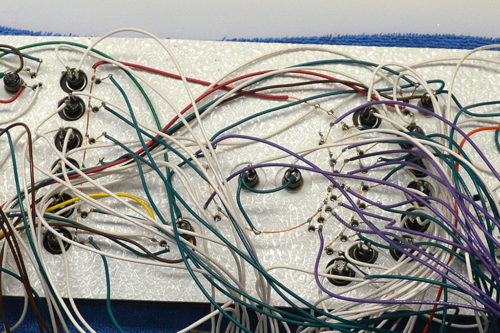

I knew it would be crowded on the backside but I didn’t realize it would be this crowded. It definitely made for some interesting body contortions trying to get the soldering iron where it was needed without touching any wires on the way.

The roundtable position LEDs and track power LEDs all needed to be tied to a single respective pin on the connector board. Point-to-point wiring would have been exceptionally difficult in such a cramped space. The LEDs are very densely packed on the board. Here is my interconnect solution (before the leads were trimmed to length).

Next up, finish the fascia and get theses babies mounted. Until next time!

Thought you had been quiet Alan, but “quiet” clearly meant “extremely busy” in this case.

Tremendous achievement and each unit is a work of art.

Looking forward to the next steps …..

Rob

What a beautiful job you did. Very nice indeed.

Hi Alan! Remarkably awesome work! Did you ever consider a custom-made printed circuit board for your panels? Prolly too much extra work…

Clark

Thanks guys.

Clark, PCB was the original plan. I wanted to avoid all the messy point-to-point wiring. Unfortunately, 17″ wide positive resist PCB is not available. Since each panel board is different and I need only one of each the cost to have them professionally fabricated would have been astronomical. The change was detailed here: https://lkorailroad.com/control-panels-part-iii/

where are you? Its like you’ve been sent away. Ive been following your build from day 1 and have withdrawl pains. Please post more shots. I’m really interested in how the control panels are working out.

Thanks for any reply,

Gary

Hi Gary. Sorry about the pains. I made a new post. No trains yet but getting very close.

Alan, I’ve stumbled across your blog recently and have devoured the entire story. I enjoy your craft, and it makes me wonder what your day job is. I’m in the field of architecture, and the holistic knowledge base of model railroading has assisted my career, and also materialized on your layout.

I’ve been building a small layout myself, and your beautiful control panels remind me of my own that I built. It is more of a control drawer, but it has the same idea. Feel free to check it out! https://www.youtube.com/watch?v=0JzhguO-ib4

Looking forward to more progress!

Hi Mitchell. Glad to hear you are enjoying the LK&O journey. So am I! I no longer have a day job. Retired March 2020. Before that I had a career in the paint industry. Not as much fun as model railroading.

Watched your video. I see the resemblance in the panels. Nice work you did there.