I don’t have an update for you just yet on the sub-roadbed progress. Mostly because I haven’t taken any pictures and there isn’t much to see if I did. All of the lap joints have been glued. Otherwise, nothing more has happened. It is summer so outside activities take precedence over the train room. I have also done considerable travel this summer leaving precious little time spent working on the railroad. But that doesn’t keep me from thinking about the next steps.

This before that…

Once the sub-roadbed is in place, risers constructed and positioned, and cork roadbed placed it will be time to begin the actual trackwork. Beyond the obvious laying of track there is considerable wiring below that will need to be completed. As with so many things, it is a case of do this before doing that. A few posts ago I described the issue and solution concerning Tortoise switch machine control. Couldn’t begin mounting Tortoises until I knew what the control arrangement would be. A case of do this before doing that. Track wiring under the sub-roadbed is a similar situation.

Power to the rails…

The layout will be divided into electrical subsections or circuits, much like a house is wired with various circuits each on their own circuit breaker in the load center (breaker box many call it). Model railroaders call these circuits “power districts”. In residential wiring, only the affected circuit shuts off in the event of a short circuit (over current situation), not the whole house. The railroad will be the same. Instead of rooms on circuits I will have track sections on power districts. If there is a short circuit in a particular power district then only that particular district shuts off, not the whole railroad. When multiple people are running trains only the train that caused the problem is affected. Everyone else keeps on rolling assuming they are not in the same power district as the problem train.

Power district breakers (circuit breakers) for model railroads differ from house wiring circuit breakers in several key areas:

- District breakers trip extremely fast compared to house breakers. They must trip faster than the circuit breaker in the railroad power supply which is already much faster than a house circuit breaker.

- District breakers operate at 12-15v DC instead of 110-120v AC of house breakers

- District breakers trip at 3-5 amps instead of 15-100 amps for house breakers

- District breakers auto reset after a brief period – usually a few seconds or less

- District breakers are solid state electronic circuits whereas house breakers are electromechanical devices

DCC system choice makes a difference….

The choice of Digital Command Control (DCC) system makes a big difference in circuit breaker options. The stalwart systems in the marketplace are made by Digitrax, NCE, Lenz, MRC, and a few others. All of these systems send the digital command signal to the locomotive via the track rails. The control signals and the motor power supply are both on the rails at the same time. A decoder inside the locomotive separates the control signal from the motor power and then acts accordingly upon the control signals it receives. DCC can be a complicated subject and it is not the purpose of this post to go into detail about DCC. If you want a thorough explanation of DCC then I highly recommend Allan Gartner’s web site Wiring for DCC. Back to the subject at hand, there are many circuit breaker options for these type of systems – signal and motor on the rails. Below is a typical DCC electronic circuit breaker made by DCC Specialties. Here are the technical details.

DCC done differently…

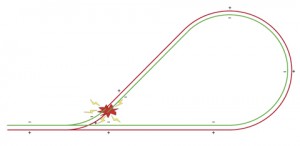

There are two DCC suppliers that are majorly different from the rest. Well, technically they are not DCC but same end result – digital control of locomotives. MTH with their DCS system and Ring Engineering with their RailPro system. ![]() I have selected RailPro as my control system. Haven’t yet purchased it, but the decision has been made. There will be many posts to come exploring the RailPro choice but for now let’s just say it is so and expand on why that matters when talking circuit breakers. The RailPro system sends the control signals directly to the decoder in the locomotive via radio bypassing the signal-on-rails arrangement of the other systems. RailPro puts only the clean 14v motor power on the rails. All of the conventional DCC circuit breakers are designed to work with both control signals and motor power present on the rails hence they don’t work in conjunction with RailPro. Ring Engineering offers their own circuit breaker designed expressly for the pure 14v DC on the rails – the AR-1 which is a combination auto reverser and circuit breaker. I know what you are thinking… “Simple enough. Use the Ring Engineering AR-1 circuit breakers on the LK&O”.

I have selected RailPro as my control system. Haven’t yet purchased it, but the decision has been made. There will be many posts to come exploring the RailPro choice but for now let’s just say it is so and expand on why that matters when talking circuit breakers. The RailPro system sends the control signals directly to the decoder in the locomotive via radio bypassing the signal-on-rails arrangement of the other systems. RailPro puts only the clean 14v motor power on the rails. All of the conventional DCC circuit breakers are designed to work with both control signals and motor power present on the rails hence they don’t work in conjunction with RailPro. Ring Engineering offers their own circuit breaker designed expressly for the pure 14v DC on the rails – the AR-1 which is a combination auto reverser and circuit breaker. I know what you are thinking… “Simple enough. Use the Ring Engineering AR-1 circuit breakers on the LK&O”.

The AR-1…

The Ring Engineering AR-1 has two aspects I don’t like: 1) it is expensive; 2) spring clip termination for a maximum wire size of 16 ga. The LK&O power district arrangement has not yet been finalized (look for an upcoming post) but suffice it to say there will likely be many districts. At $39.99 each for AR-1’s, the cost will add up fast. I would prefer a less expensive solution. The real burr under my saddle is the spring clips and maximum 16 gauge wire. DC has a lot of voltage drop over a long run of wire especially with smaller gauge wires. 12 ga wire is a common choice for track power bus to minimize voltage drop. Reversing loops, which the AR-1 is designed for, are special situations where track polarity needs to be managed to prevent a short circuit. Reversing loops are usually very short and as such do not require long lengths of bus wire. 16 ga wire is plenty suitable for reversing loops. This apparently was Ring Engineering’s design consideration for the AR-1 since it is primarily a reversing module. 16 ga makes perfect sense for a reverser. However, it makes no sense for a district circuit breaker where long lengths of heavier wire are called for. Makes me think using the AR-1 as a circuit breaker was an afterthought for Ring Engineering. I am very hesitant to wire my district buses with 16 ga wire. No, let me restate that. I will not wire my buses with 16 ga wire. They will be 12 ga wire period. If I use the AR-1 then I have to insert a short piece of 16 ga wire between the AR-1 and my 12 ga bus. That’s hokey and something I am not willing to do. So, I set out to see if a better solution could be had.

Reversing loops, which the AR-1 is designed for, are special situations where track polarity needs to be managed to prevent a short circuit. Reversing loops are usually very short and as such do not require long lengths of bus wire. 16 ga wire is plenty suitable for reversing loops. This apparently was Ring Engineering’s design consideration for the AR-1 since it is primarily a reversing module. 16 ga makes perfect sense for a reverser. However, it makes no sense for a district circuit breaker where long lengths of heavier wire are called for. Makes me think using the AR-1 as a circuit breaker was an afterthought for Ring Engineering. I am very hesitant to wire my district buses with 16 ga wire. No, let me restate that. I will not wire my buses with 16 ga wire. They will be 12 ga wire period. If I use the AR-1 then I have to insert a short piece of 16 ga wire between the AR-1 and my 12 ga bus. That’s hokey and something I am not willing to do. So, I set out to see if a better solution could be had.

An alternative…

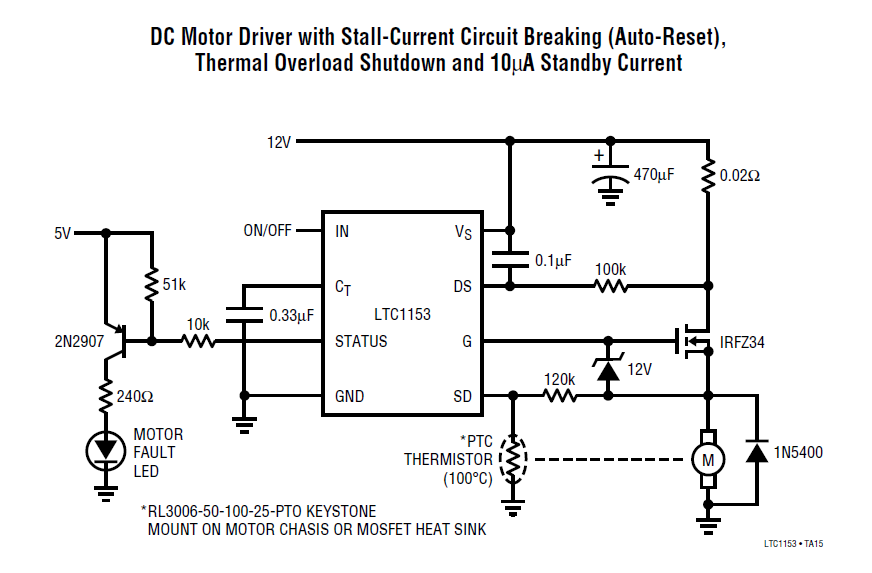

As I stated before, none of the DCC suppliers make available a circuit breaker that works on a pure DC track supply voltage. That means I had to look outside the hobby. Check out this little circuit I found in a Linear Technologies datasheet. By the description in the datasheet it sounds perfect for the application.

The LTC1153 chip turns off the transistor IRFZ34 when the current draw is greater than 4 amps. It then tries to reset itself every few seconds. If the short is still present the transistor stays off. Only after the short is removed is the transistor energized thus supplying current to the load (shown above as a motor, will be a power district on my railroad). The circuit has secondary overheating protection as well. The thermistor shown sensing motor heat will instead be mounted on the transistor heat sink to protect the circuit from overheating. Trip time for the circuit is super fast at 0.2 milliseconds. Details are in the LTC1153 datasheet. Another nice feature of this circuit is an indicator LED to indicate the breaker has been tripped. A quick price out shows a single copy of this circuit can be built for less than $10 in parts not including the circuit board. China parts in quantity from eBay reduces the cost even further to build multiple copies.

Component values…

PWR-75 is the RailPro power supply I plan to use. Actually, two of them. Again, to minimize voltage drop across the long runs of track power bus under the layout, I am going to position the PWR-75’s on opposite sides of the room essentially dividing the bus length into thirds. Something like this: ——————– PS ——————– PS ——————–

This arrangement will keep the maximum wire run to less than 20′ in any direction. The PWR-75 has a rated output of 5.3A @ 14V. Voltage drop across 20′ of 12 ga wire at the full 5.3 amps = 0.34V or 2.4% which is plenty acceptable.

This arrangement will keep the maximum wire run to less than 20′ in any direction. The PWR-75 has a rated output of 5.3A @ 14V. Voltage drop across 20′ of 12 ga wire at the full 5.3 amps = 0.34V or 2.4% which is plenty acceptable.

Since the PWR-75 internal breaker will trip at 5.3A (let’s be safe and call it 5A), the district breakers must trip at less than 5A. I think 4A is a good value for the district breakers. A 1 amp spread between the PWR-75 trip point and a district breaker trip point will assure the district trips before the power supply while still providing plenty of current to the district. Tim Ring of Ring Engineering was kind enough to provide the value 0.25A – the average current draw of a RailPro LM2S decoder in an HO locomotive. That means 4 amps will be sufficient for 16 locomotives in any one district. More than plenty.

The LTC1153 trips when there is 100mV drop across the sense resistor (shown in schematic as 0.02Ω). In my application, the supply voltage is 14v and the desired trip point is 4A. Apply ohm’s law and we see the sense resistor needs to be 0.025Ω and must dissipate 0.3 watts of power. Don’t want the sense resistor operating anywhere near its rated wattage so the value must be at least doubled to 0.8W or in common values 1W. Digikey has a 3W unit that is only 84¢ #MPR3JB25L0-ND.

R = E / I ——- 0.100v / 4A = 0.025Ω

P = E * I ——- 0.100v * 4 A = 0.4 W (doubled = 0.8W)

The only other change to the schematic values I am aware of is a 14v zener diode in place of the 12v shown – Digikey #1N5244B-TPTR-ND.

I am going to build one of these circuits and test it using my bench power supply just to make sure it works as intended. If it does then I have possibly found my better solution. The circuit will still have to be tested with a real PWR-75 to make sure it is fast tripping enough. Of course that final test will have to wait until I actually have a PWR-75. Assuming all goes well, you have to admit that at less than $10 ea and 12 ga wire connections this little circuit may be just what the doctor ordered!