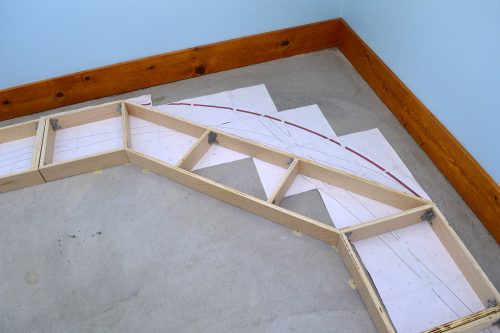

All of the lower deck benchwork, except staging, is roughed in. Next step is to get it temporarily up on the wall with shelf brackets to make sure the geometry works. It looks good according to the markers on the floor.

Here are way more photos than the subject deserves. Gotta love the freeness of digital photography!

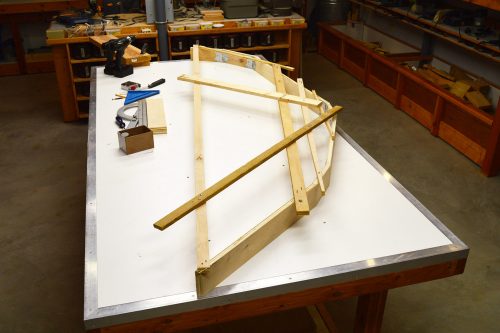

The upper benchwork was built in-place on top of a full track plan print laying on the floor. While being an accurate way to go about it, it sure was rough on the knees and back. I’m 10 years older now and did not want to go through that again. So, the lower deck was built entirely on the workbench in the shop using the floor markings, and sometimes the upper benchwork, as a fit quality check.

Length and angle measurements were taken in the train room and then duplicated on the bench in cut and assembled material. The process was straightforward with rectangular sections and even the 90 degree corners. The fact that the workbench is a true 90 degree corner rectangle greatly aided in construction.

It was the multi-segmented, multi-angled outside profiles that proved to be challenging. Led to some unusual fixturing that permitted me to pick up the assembly and carry it to the workbench without any flexing in the angles. Looks crude but worked great. Once on the workbench it was clamped down in-place, straps removed, and build out completed.

Next up, the brackets. More about that in the next post.